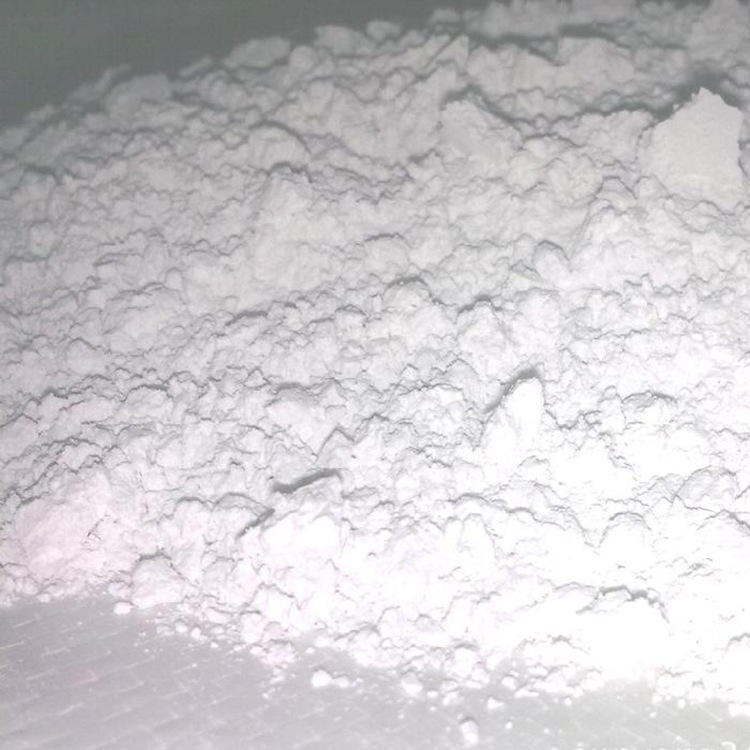

White fiber gypsum powder

Gypsum fiber(gypsum whisker, calcium sulfate whisker)

English Name: Calcium Sulfate Whisker, Abbreviation: CSW or SW;

Molecular formula: CaSO4

| Variety | Feature | Performance | Application |

| White fiber gypsum powder | Good whiteness, high finish, high strength, high purity. | Whiteness >85%, initial setting ≥8, final setting <25, consistency 70%, flexure 8MPa, compression 18MPa. | Used in decoration, building materials, sculpture, exquisite ceramic mold. |

ss

Calcium sulfate whisker is a fibrous (whisker) single crystal with a uniform cross-section, complete shape, and perfect internal structure, which is grown in the form of a single crystal by artificial control. Its basic performance indicators are as follows:

| Item | index | Item | Index |

| Composition of whisker | CaSO4 | tensile strength(GPa) | 20.5 |

| density(g/cm3) | 2.96 | tensile modulus(GPa) | 178 |

| Density of looseness(g/cm3) | 0.1-0.4 | length(um) | 20-100 |

| diameter(um) | 1-3 | water solubility(22℃ppm) | 1200 |

| melting point(℃) | 1450 | hardness(Mohs) | 3 |

| heat resistance(℃) | 1000 | RI (refractive index) | 1.585 |

Calcium sulfate whisker can be divided into two water (CaSO4•2H2O), half water (CaSO4•0.5H2O) and anhydrous (CaSO4).

Gypsum fiber is a fibrous single crystal of calcium sulfate, white loose needle, with perfect structure, complete shape, specific cross section, stable size, its average length-diameter ratio is generally 20~50. Slightly soluble in water and neutral in aqueous solution. It has the fineness of granular packing, the length-diameter ratio of short fiber packing, high temperature resistance, acid and alkali resistance, chemical corrosion resistance, good toughness, good electrical insulation, high strength, easy surface treatment, good compatibility with resin, plastic and rubber, can be evenly dispersed, pH value is close to neutral. Excellent enhanced function and flame retardant. Compared with other inorganic whisker, calcium sulfate whisker is a non-toxic green material.